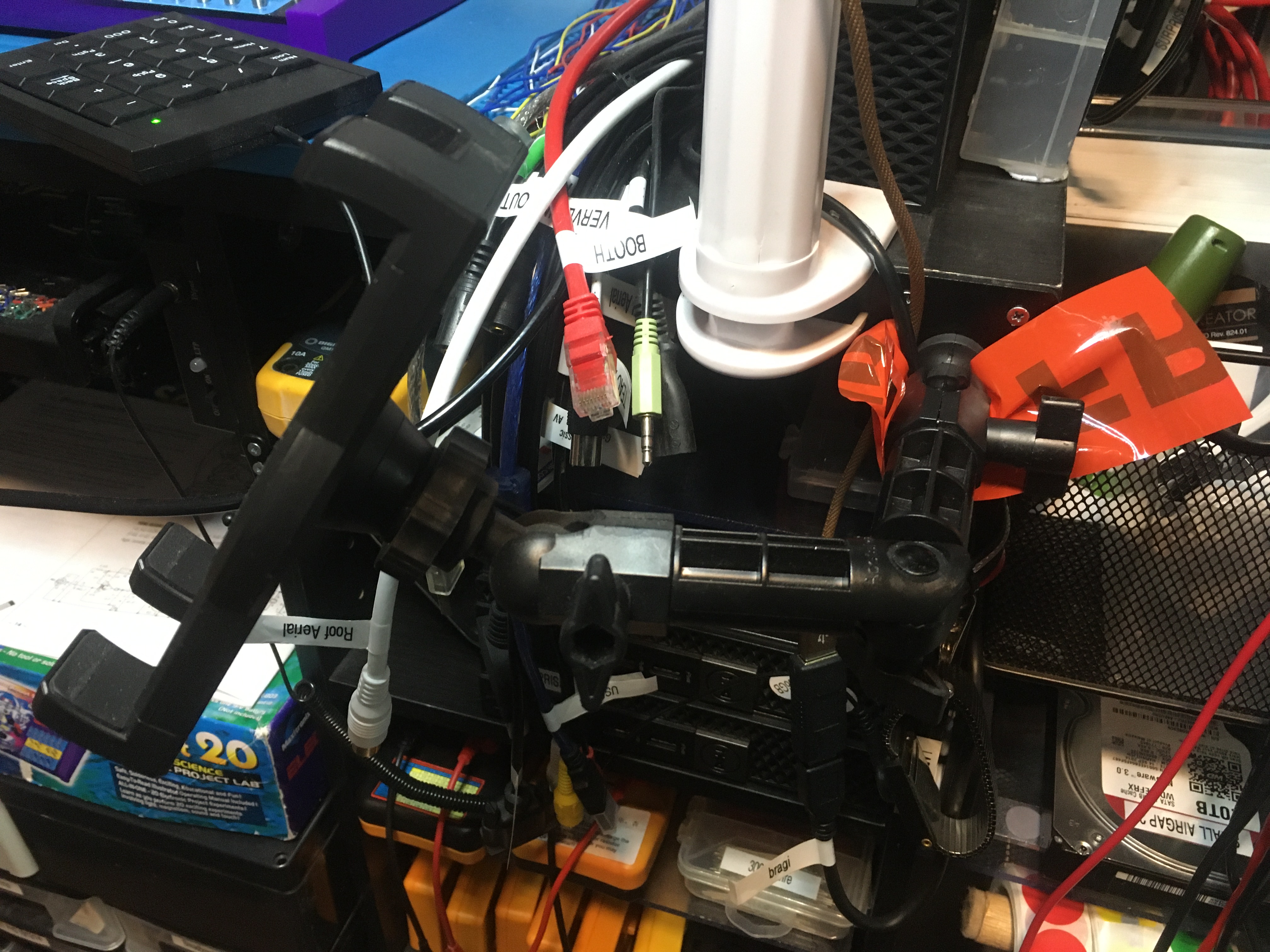

Over time the joint on this holder comes a bit loose and I have to tighten it back up again. This time when I tightened it I dumped a whole tube of superglue in there. Hopefully that holds it!

I do put it under quite a bit of strain. In addition to holding the number pad for the booth, it also holds a bunch of my cables which I hang over it.

That red tape you can see I put there to stop the glue from leaking too much. I will remove that once the glue is dry.

Can’t really tell what I’m looking at there, but one thing I would say is that CA (super) glue is quite fragile: it does not like shock loads, and cracks readily. It’s strong, yes, but any sudden impact is likely to dislodge it.

Again, can’t tell if that’s a factor here, but something to consider. Epoxy is much more flexible, and can be a better choice for some applications.

Regarding what you’re looking at: you can see the red tape top right. That is under the joint which I have glued into place. You can see to the right of the joint a wing nut which is used to clamp the joint closed. That clamping is not strong enough and comes loose over time. That is why I have added the glue.

Thanks for the tip about the epoxy! I have ordered some Araldite which I intend to use on this joint as well. https://www.ebay.com.au/itm/235494196436

In retrospect I could have done a better job. Live and learn! Thanks again.