I have a new post on Hackaday: Superconductivity News: What Makes Floquet Majorana Fermions Special For Quantum Computing?

Consumer Rights Wiki

Today Louis Rossmann announced his Consumer Rights Wiki over here: US Senator wakes up to the fact that we don’t own things anymore, writes letter to the FTC about it. I wish him every success with this project!

Elle Cordova: Grammarian vs Errorist II

Oh man, Elle Cordova is so insanely creative. It’s gonna be a long time before the AI puts her out of work! This recent one was brilliant: Grammarian vs Errorist II (it’s part II in Grammarian vs Errorist series). Here’s my favorite so far: Virtual Assistants.

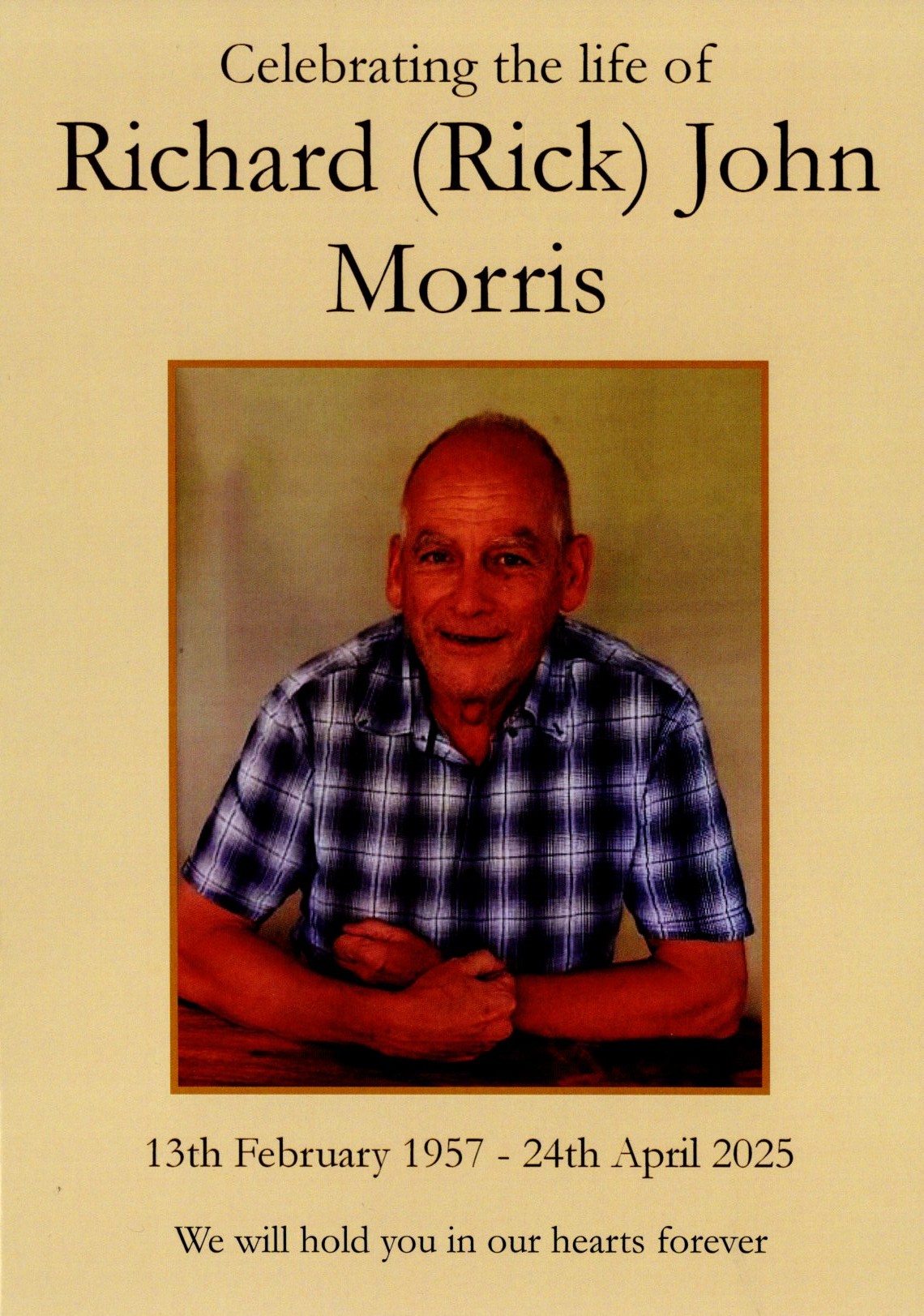

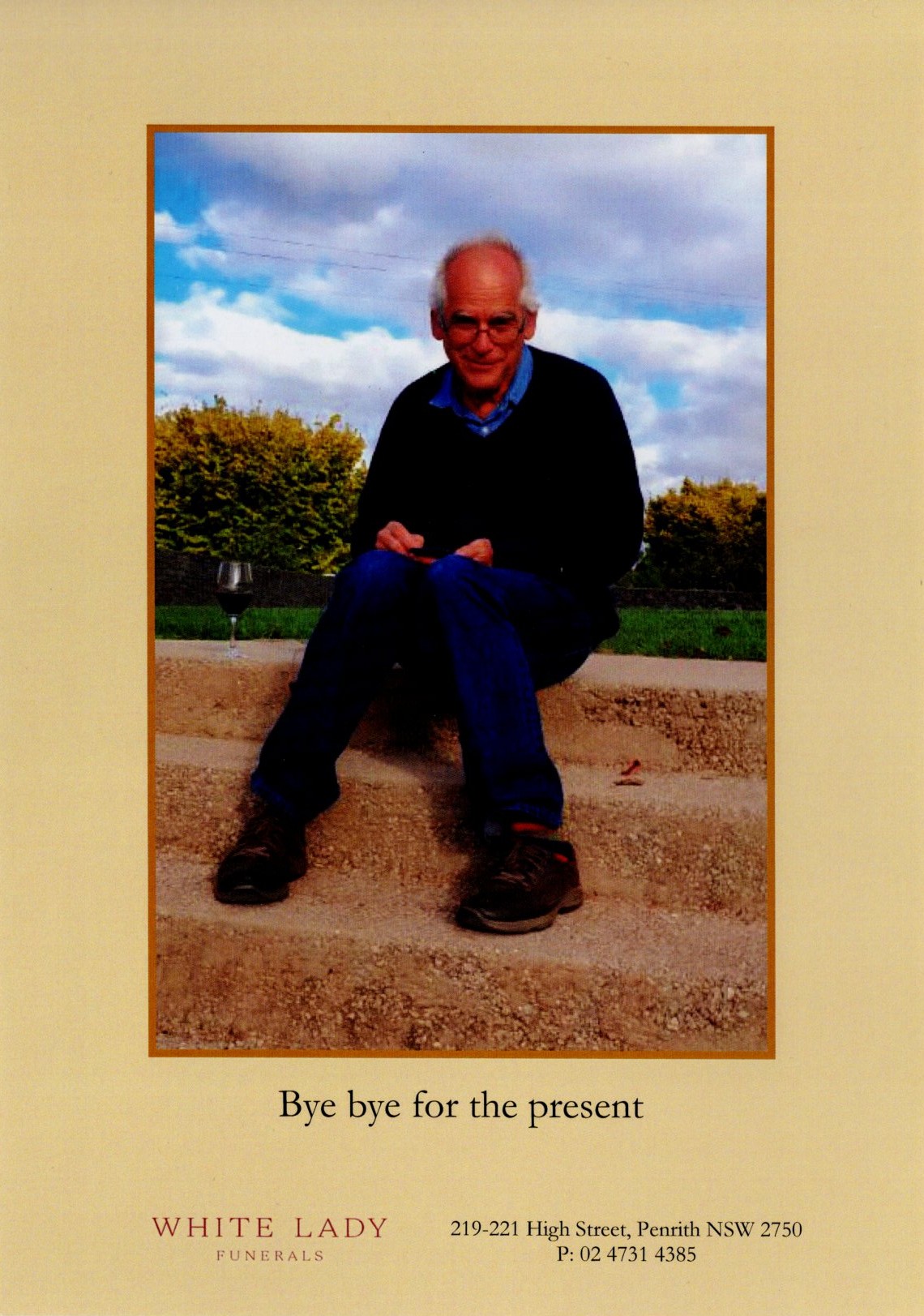

RIP Rick Morris

I just received some sad news from my friend Shahriar: our old school teacher Rick Morris has passed away.

The funeral is 2pm in Leura today, 7th May.

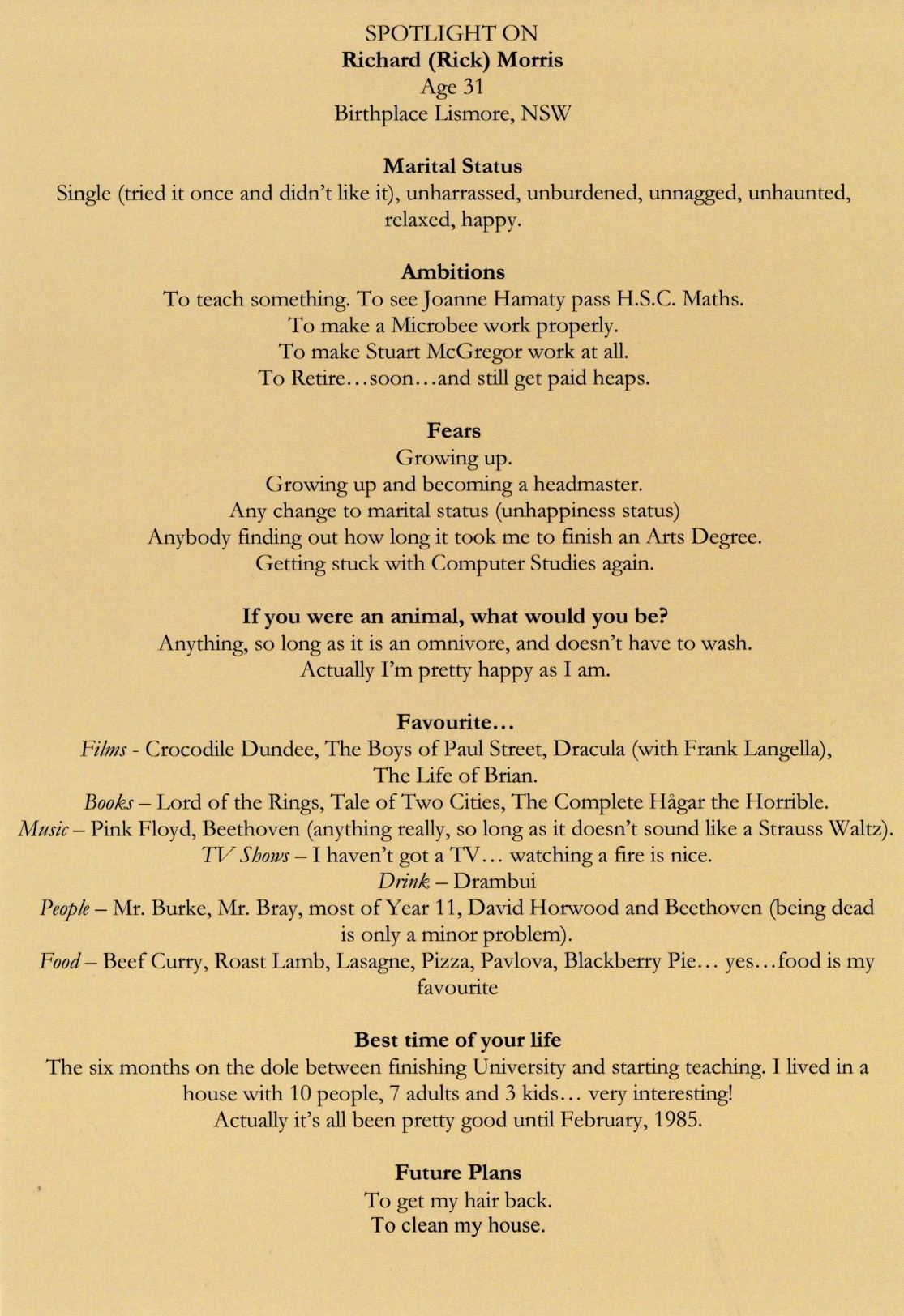

Mr Morris was perhaps the most central figure in putting me on the path to computer programming. He used to run the computer lab at our high school and he was our computers teacher in junior high. I had him as my advanced mathematics teacher too.

You know how in Excel if you want a relative reference you use something like ‘B8’ and if you want an absolute reference you use the dollar sign as e.g. ‘$B$8’. Well it was Mr Morris who taught me that, some time back in the early 90s. I’ve been using that syntax my whole life, and every time I do I think of Mr Morris.

It wasn’t so long ago that Shahriar and I caught up with Mr Morris for drinks at the Lappo. Of course we didn’t know at the time that would be the last time we’d ever see him. At least we did have that time together before we lost him.

I will miss his quiet intelligence and his big laugh.

p.s. I just got back from the funeral. Apparently he died suddenly from a stroke on 24th April. It was a beautiful ceremony. 50/50 laughing and crying. They had speeches, poems, photos, and music. They even played the Star Wars anthem! I was confused and accidentally went up with the family when it was time for family members to come to the front and pay their respects. Whoops! I think Mr Morris would have laughed.

Order of Service

Channel News #7: Announcing ITL Wiki and Pre-Reading for LtAoE | In The Lab With Jay Jay

This post is part of my video blog and you can find more information about this video over here.

You can support this channel on Patreon: patreon.com/JohnElliotV

Silly Job Title: Connector Kingpin.

In this video I tell you about the new ITL Wiki.

The notes for Learning the Art of Electronics are there: ITL Wiki § Learning the Art of Electronics.

I am running late with Lab #1 from Learning the Art of Electronics. That video was meant to come out today, but I’ve pushed it back to next Tuesday so I have time to prepare the notes and record the lab.

See you next Tuesday? :)

Thanks very much for watching! And please remember to hit like and subscribe! :)

Following is a product I use picked at random from my collection which may appear in my videos. Clicking through on this to find and click on the green affiliate links before purchasing from eBay or AliExpress is a great way to support the channel at no cost to you. Thanks!

Ausum 25 In 1 Precision Screwdriver Set notes notes |

Let’s go shopping!

Spectrum Analyzer using Beaglebone Black and RTL-SDR

I want to build myself one of these: Spectrum Analyzer using Beaglebone Black and RTL-SDR.

Lancing College Shares Critical Design Review For UK CanSat Entry

I have a new post on Hackaday: Lancing College Shares Critical Design Review For UK CanSat Entry.

MediaWiki upgrade for John’s wiki

I upgraded my John’s wiki today from MediaWiki 1.42.1 to 1.43.1.

Getting Started With ATtiny Configurable Custom Logic (CCL)

I have a new post on Hackaday: Getting Started With ATtiny Configurable Custom Logic (CCL).

Interlude #16: False Start for Learning the Art of Electronics | In The Lab With Jay Jay

This post is part of my video blog and you can find more information about this video over here.

You can support this channel on Patreon: patreon.com/JohnElliotV

Silly Job Title: Lightning Tamer.

This project’s homepage is here: John’s wiki § Learning the Art of Electronics.

This video is me making a false start on the Learning the Art of Electronics series which I am just about to embark on. What happened was after I got a bit more than two hours into recording the video for the first lab exercise I realized that it was taking too long with my approach. I didn’t want to make another twelve hour video! I was planning to go through the literature in painstaking detail and cover everything, but it turned out there was way too much material for that approach to be feasible.

What I am planning to do instead for the actual first video (due out next Tuesday) is do all the reading by myself in advance and then offer a brief summary and some recommended reading. I’m going to try to make the bulk of the video the actual practical experiment/circuit and leave the reading out.

But since I recorded the video for this “false start” I figured there’d be no harm in posting it by itself. Most of this video is the Appendix O material from The Art of Electronics 3ed which is a brief introduction to oscilloscopes.

In this video we mention CMOS technology, particularly MOSFETs.

We mention the Josephson effect which can cause a current to flow across superconductors in the absence of an applied voltage.

The SI size prefixes are documented on my wiki.

In this video we learn about voltage and current.

We take a close look at Appendix O in AoE which introduces the oscilloscope and mentions delay lines.

The oscilloscope appendix makes mention of Asimov’s short story from 1960, Thiotimoline and the Space Age.

We mention quantization, Planck units, and Zeno’s paradox.

I show you can illustration from Getting Started in Electronics.

If you’re planning to follow along with the series the pre-reading for the first video coming out on Tuesday is: E&M ch. 1, 2; PoEC ch. 1; AoE app. A, ch. 1; LtAoE ch. 1N, 1L.

Thanks very much for watching! And please remember to hit like and subscribe! :)

Following is a product I use picked at random from my collection which may appear in my videos. Clicking through on this to find and click on the green affiliate links before purchasing from eBay or AliExpress is a great way to support the channel at no cost to you. Thanks!

ANENG A3005 Pen Type Handheld Multimeter notes notes |

Let’s go shopping!