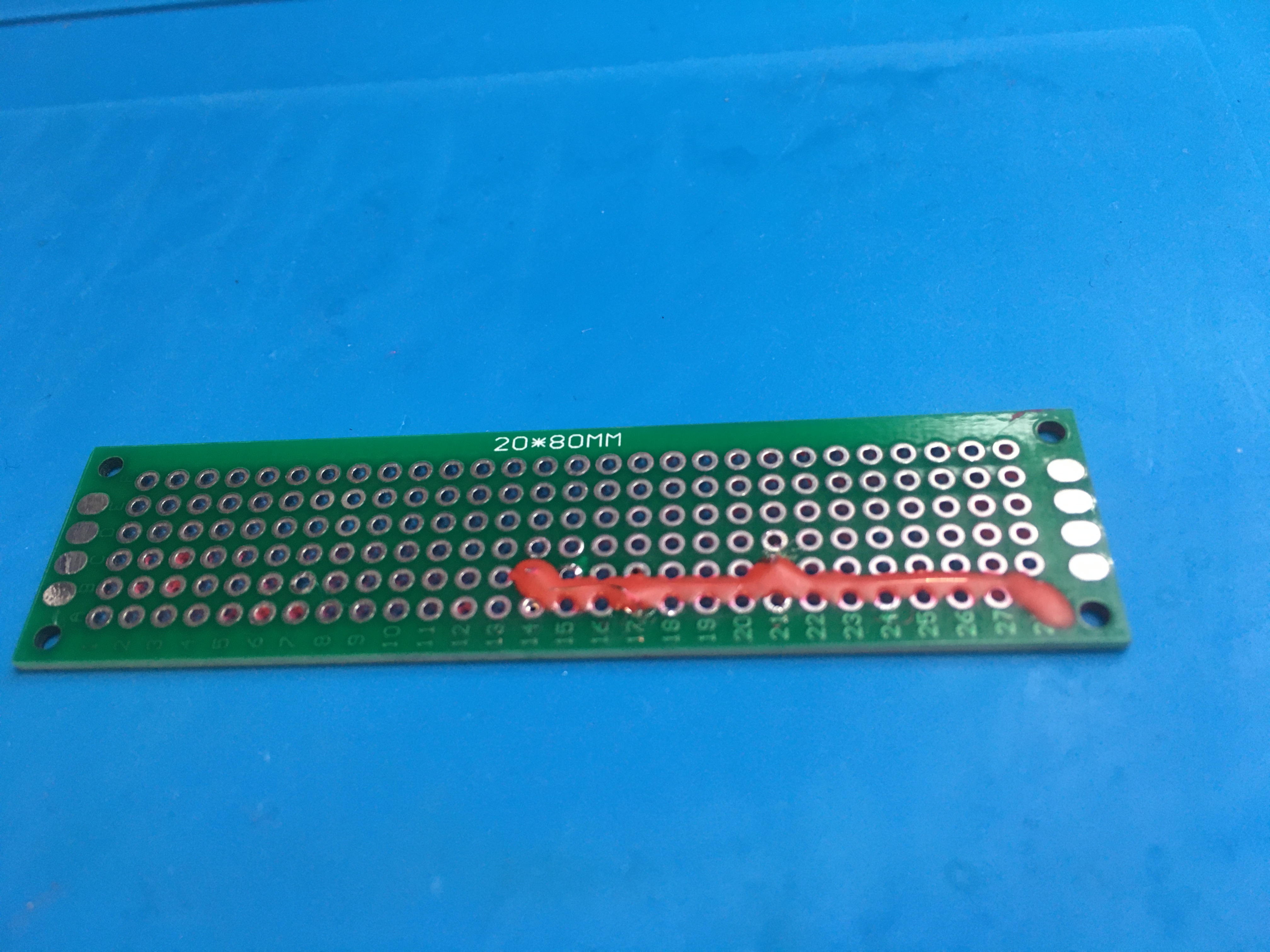

I just finished recording a video for In The Lab With Jay Jay wherein I install some bodge wires using my recently learned techniques. Below is the finished result. It’s actually three bodge wires joined together. A small one (0.07mm, 0.003″) from 28A to 21B, a medium one (0.16mm, 0.006″) from 21B to 17A, and a big one (0.31mm, 0.012″) from 17A to 14B. The job was finished with some red solder mask. I will have the video up shortly!

Daily Archives: 2023-09-05 [Tuesday]

Tip indicator

I have a working theory that you can tell how good an electrical engineer is by the type of soldering iron tip they use.

- Conical tip: Novice

- Bevel tip: Journeyman

- Chisel tip: Master Craftsman

And no one uses a knife tip, I mean come on, be serious.

Bodge wire

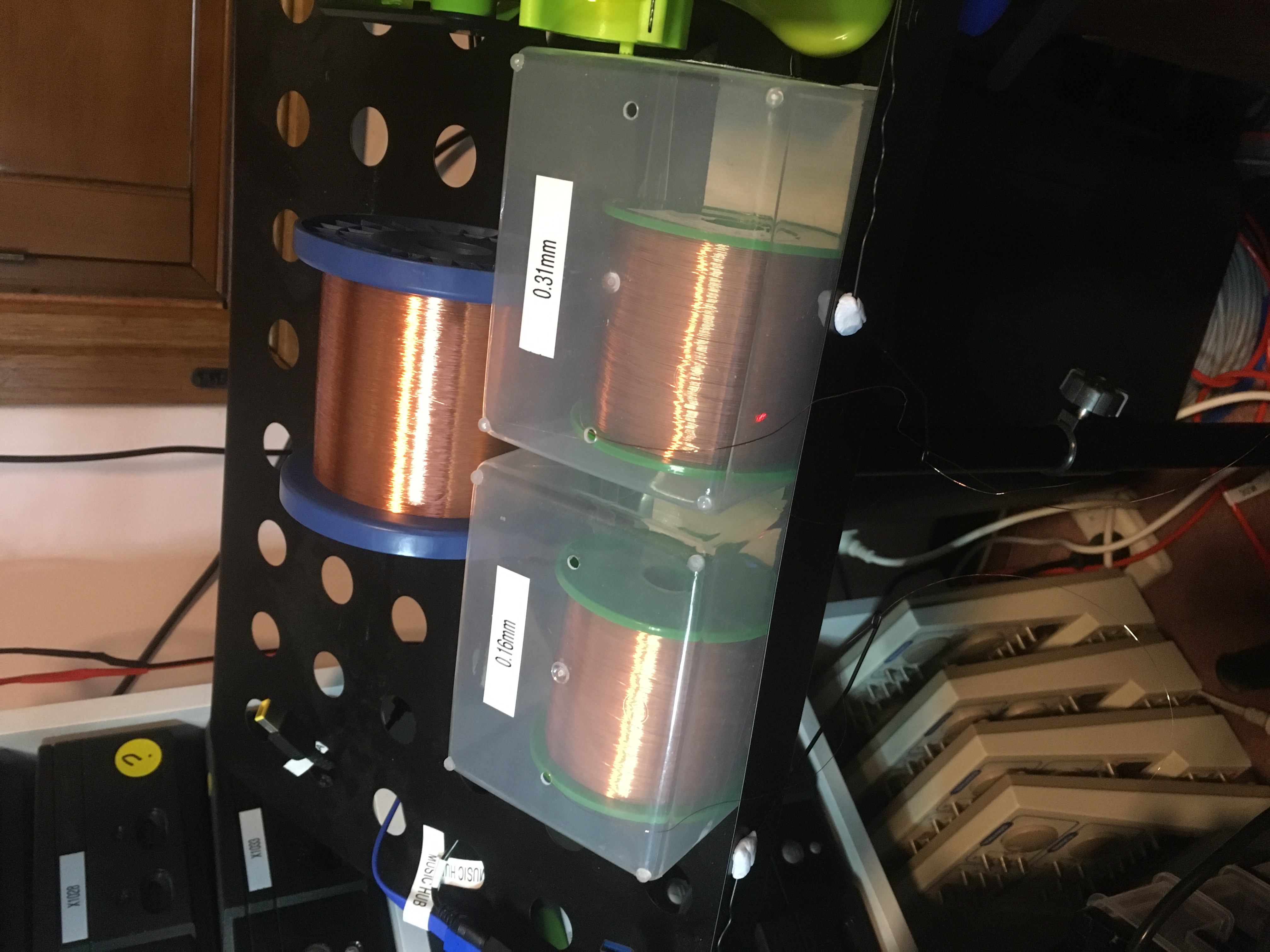

Thanks to my mate Bruce from Branchus Creations and his wire size suggestions I got a bunch of bodge wire for doing PCB repairs, being 1KG Enameled Copper Winding Wire 0.05 0.06 0.1 0.13 0.2 0.4 0.8 0.5mm 0.65 1.0 1.4 1.3mm Cable Magnet Wire Winding Wire Coil red. I got:

- 0.07mm (back)

- 0.16mm (front left)

- 0.31mm (front right)

It would have been more convenient for me if the 0.07mm wire had have been on a smaller roll like the other two, but we can’t have everything. I’ve been thinking I might get some sort of wire rack, but I’m not sure where I would keep it.

I wasn’t sure exactly how I would go about cleaning enamel off the wire for soldering, so I asked ChatGPT, which gave me a number of options:

- Mechanical stripping

- Thermal stripping

- Chemical stripping

I think what I will actually try is just tinning the ends with my soldering iron and some fresh solder and see if that will burn off just a little bit of enamel on the tips, leaving me with a tinned wire I can easily solder into place.

JST PHD Connector Crimping

I found a good video that shows how to crimp a JST PHD connector: JST Connector Crimping. When crimping these JST connectors I use my ENGINEER PA-09 crimping tool. I use a 1.4mm crimp for the wire and a 1.9mm crimp for the insulation.